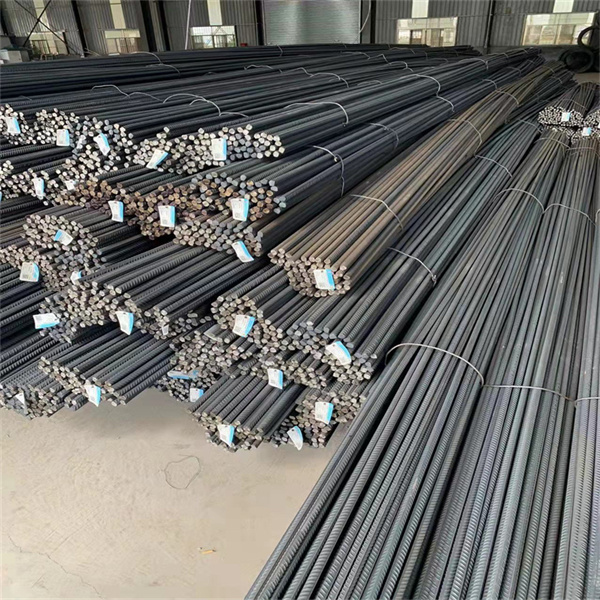

I-HRB355 hrb400 hrb500 hrb500 I-8MM 10m 14mm 16mm I-16mm Ribbed Bar Bar Bar Bar

ukwahlulahlula

Ibha yentsimbi eshushu eshushu yahlulwe yangamaBanga amathathu: HRB335 (IBakala lakudala lingama-20mns), iBakala lesithathu HRB400 (IBakala lakudala (iBanga laBadala liyi-20mnsnb, kunye neBanga lesine le-HRB500.

Zimbini iindlela ezisetyenziswayo zokuhlela zokuqinisa imivalo:Inye kukuhlela ngokwemilo yejometri, kwaye enye kukuhlela okanye ukwahlula-hlula ngokwemilo yomnqamlezo wecandelo lezinto ezixineneyo kunye nokuvalwa kwemivalo. Chwetheza ii-II.

Okwesibini kukuhlelwa kwentsebenzo (ibanga), njengokuphunyezwa okukhoyo ngoku kwilizwe lam, i-repur1499.2-2008 Inqanaba; Kwinqanaba lemizi-mveliso laseJapan (ji sg3112), imivalo yentsimbi yahlulwe ngokwamanqanaba ama-5 ngokweempawu zabo ezibanzi; Kumgangatho weBritane (Bs4461), amabakala amaninzi eemvavanyo zovavanyo lwentsebenzo zichazwe. Ukongeza, imivalo yensimbi inokubekwa ngokusetyenziswa, njengokuvalwa kwentsimbi yentsimbi yokuqiniswa kwekhonkrithi kunye nemivalo yentsimbi ephathwayo yekhonkrithi.

inkalo

1) Uluhlu lweedayala ze-diameter kunye nobubanzi obucetyiswayo

Ububanzi bemigca yensimbi busuka kwi-6 ukuya kwi-50mm, kunye nomgangatho weenqanawa ezinconyelweyo ze-6, 8, 12, 14, 32, kunye ne-50mm.

2) ukuphambuka okuvumelekileyo kobume bomphezulu kunye nobungakanani bebhadi yensimbi yensimbi

Imigaqo yoyilo yemivalo yentsimbi yentsimbi kufuneka ifezekise ezi mfuno zilandelayo:

I-Angle β phakathi kwembambo elinqamlezayo kunye ne-axis yentsimbi akufuneki ukuba ingaphantsi kwama-45 degrees. Xa i-engile equkiweyo ayiphezulu kwe-70 degrees, indlela yokuvalwa kweendawo eziguqukayo kumacala omabini akwibar yentsimbi kufuneka aphathwe ngokuchaseneyo;

Isithuba esithile esiyi-l kwimivalo yokuhamba ngokungafanelekanga ukuba ingabi ngaphezu kwe-0.7 uphinda-phinde.

I-angle α phakathi kwecala le-rib efihlakeleyo kunye nomphezulu webhani yensimbi awuyi kuba ngaphantsi kwama-45 degrees;

Isixa se-GAPS (kubandakanya ububanzi beembambo zexesha elide) kwiziphelo ze-ribes ezinqamlezileyo kumacala aphezulu kwi-bar yensimbi ayiyi kuba ngaphezulu kwe-20% yomjikelezo wentsimbi;

Xa idayimitha etyunjiweyo yebha yentsimbi ayingaphezulu kwe-12mm, indawo ye-rib yesalathisi akufuneki ibe ngaphantsi kwe-0.055; Xa idayimitha yoLungiso i-14mm kunye ne-16mm, indawo ye-rib ye-rib akufuneki ibe ngaphantsi kwe-0.060; Xa idayimitha yoLungu inkulu kune-16mm, indawo ye-rib ye-rib akufuneki ibe ngaphantsi kwe-0.065. Jonga isiHlomelo C sokubalwa kwendawo yerib yesihlobo.

Imivalo yensimbi yensimbi ngokubanzi inemivalo emide, kwaye nakwakhona nawabo bangomvumbi;

3) ubude kunye nokuphambuka okuvumelekileyo

Nye. ubude

Imivalo yensimbi ihlala ihanjiswa ngobude obusisigxina, kwaye ubude bokuhanjiswa kweenkonzo kufuneka ziboniswe kwimvumelwano;

Imivalo yensimbi inokuhanjiswa kwi-roll, uluhlu ngalunye lufanele ukuba lube yibha yentsimbi, kunye ne-5% yenani le-rolls nganye kwi-batch nganye (ngaphantsi kwe-rolls ezimbini) iqulethe imivalo emibini yentsimbi. Ubunzima bediski kunye needayimitha zediski zimiselwa ngokuthetha-thethano phakathi komthengisi kunye nomthengi.

b. Ubude bokunyamezelana

Xa ubude obumiselweyo zisiwe, ukuphambuka okuvumelekileyo kubude bebhani yensimbi ayisiyo ngaphezulu kwe-25mm;

Xa ubude obuncinci obufunekayo, ukuphambuka yi- 50mm;

Xa ubude obukhulu obufunekayo, ukuphambuka kwe--50mm.

c. I-curvature kunye neziphelo

Ukuphela kwebha yentsimbi kufuneka kunqunyulwe ngqo, kwaye ishenxisi yendawo ayiyi kuchaphazela ukusetyenziswa

Inkcazo-ntetho

shibshiwojnujhuaduanonjiiduandonodie

irrtg

intwasahlobo

entshona

Asjgowdwywhaogrhg