Choosing the right steel plate is crucial to ensuring the success of your project. Whether it is used for building structures or manufacturing, the right steel plate can improve efficiency, durability and cost-effectiveness. Here are some key steps to choosing the right steel plate for your needs:

1. Determine the needs: First, clarify the specific requirements of your project for the steel plate. This includes understanding the size, thickness, strength and corrosion resistance of the required steel plate. Different projects may require different types of steel plates. For example, construction projects may require different steel plates than mechanical manufacturing.

2. Choose the material: The material of the steel plate determines its performance characteristics. Common steel plate materials include carbon steel, alloy steel and stainless steel. Each material has its specific uses and advantages. For example, stainless steel plates are widely used in chemical processing equipment due to their corrosion resistance.

3. Quality standards: High-quality steel plates should meet national or international quality standards. Check whether the steel plate has material certification, such as ASTM or AISI standards, which helps ensure that the steel plate you purchase is of reliable quality.

4. Supplier selection: It is essential to choose a reputable supplier. A supplier’s history, customer reviews, and certifications can provide important information about their reliability.

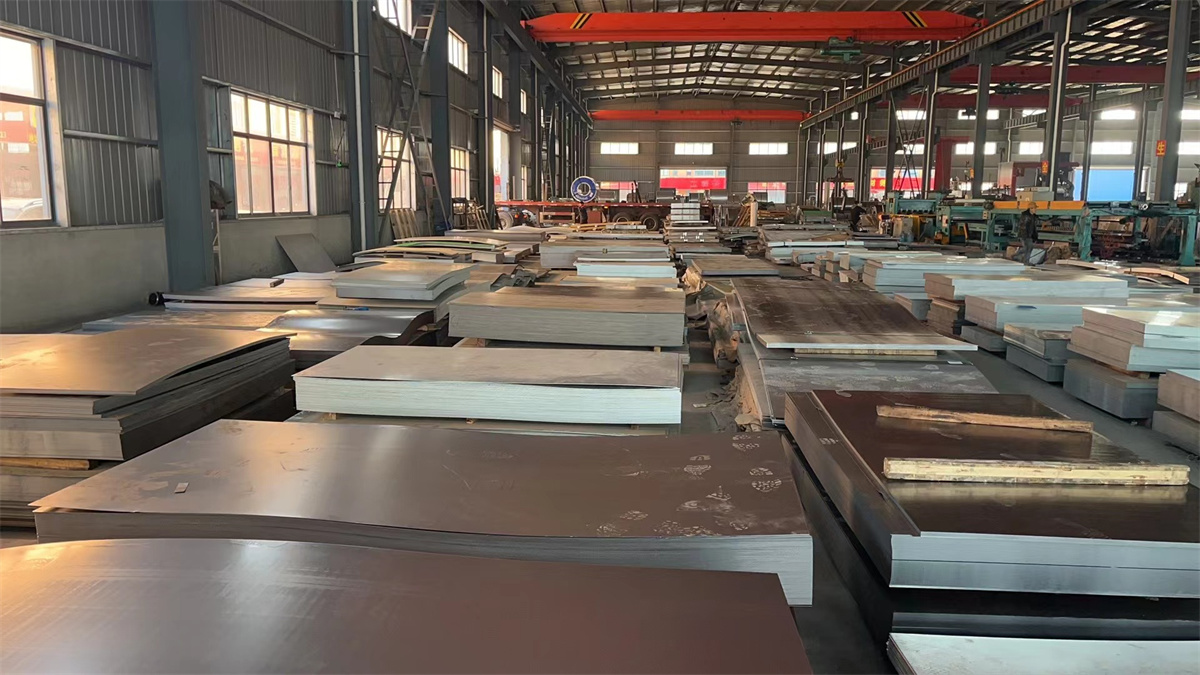

5. Inspect the steel plate: Before purchasing, carefully inspect the surface quality of the steel plate. Avoid choosing steel plates with folds, pitting, scars, or cracks, which are all signs of low-quality steel plates.

6. Price comparison: Get quotes from multiple suppliers and compare prices and quality. Sometimes, a higher price may mean better quality and service.

7. Consider environmental factors: If your project is located in a special environment

Post time: Oct-15-2024