Cold rolled plate SPCC wholesale cold rolled plate mirror drawing cold rolled coil size cutting plane thickened cold rolled steel plate

PRODUCT DESCRIPTION

Hot rolling

Hot rolling takes slab (mainly continuous casting billet) as raw material and makes strip steel from roughing mill and finishing mill after heating. The hot steel strip from the last finishing mill is cooled to the set temperature by laminar flow, and is rolled into steel strip coil by the coiler. The cooled steel strip coil is processed into steel plate, flat coil and longitudinal strip products by different finishing lines (leveling, straightening, transverse or longitudinal cutting, inspection, weighing, packaging and marking, etc.) according to different needs of users. To put it more simply, a slab of steel is heated (the kind of red, hot piece of steel that burns on TV), rolled several times, trimmed, and straightened into a steel plate. This is called hot rolling.

Cold rolling

Cold rolling: with hot rolled steel coil as raw material, after pickling to remove the oxide skin for cold continuous rolling, the finished product is rolled hard roll, because of the cold hardening caused by continuous cold deformation of the rolled hard roll strength, hardness, toughness and plastic index decline, so the stamping performance will deteriorate, can only be used for simple deformation parts. Hard roll can be used as raw material in hot dip galvanizing plant because hot dip galvanizing units are equipped with annealing line. Rolled hard coil weight is generally 6~13.5 tons, steel coil at room temperature, hot rolled pickling coil continuous rolling. The inner diameter is 610mm.

Product features: Because it has not been annealed, its hardness is very high (HRB is greater than 90), the machining performance is very poor, can only be simple directional bending processing less than 90 degrees (perpendicular to the direction of coiling).

To put it simply, cold rolling is processed and rolled on the basis of hot rolled plate and roll. Generally speaking, it is a process of hot rolling - pickling - cold rolling.

Cold rolling is processed by hot rolled plate at normal temperature, although the steel plate will be heated up during the processing process because of rolling, but still called cold rolling. As a result of hot rolling through continuous cold deformation of cold rolling, the mechanical properties are relatively poor, the hardness is too high. Must be annealed to restore its mechanical properties, not annealed called rolled hard roll. Rolled hard roll is generally used to do without bending, stretching products.

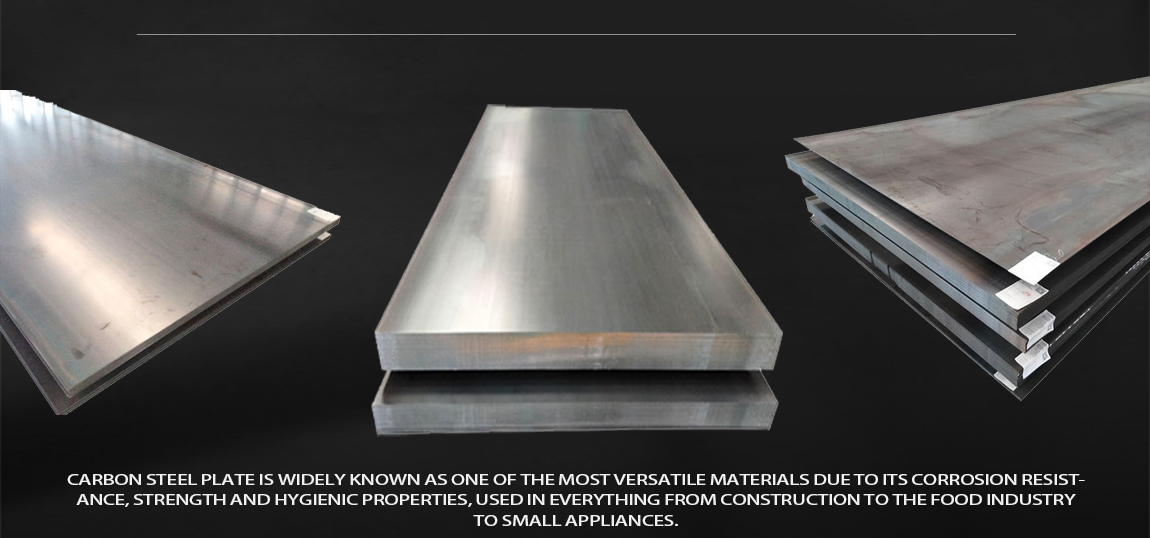

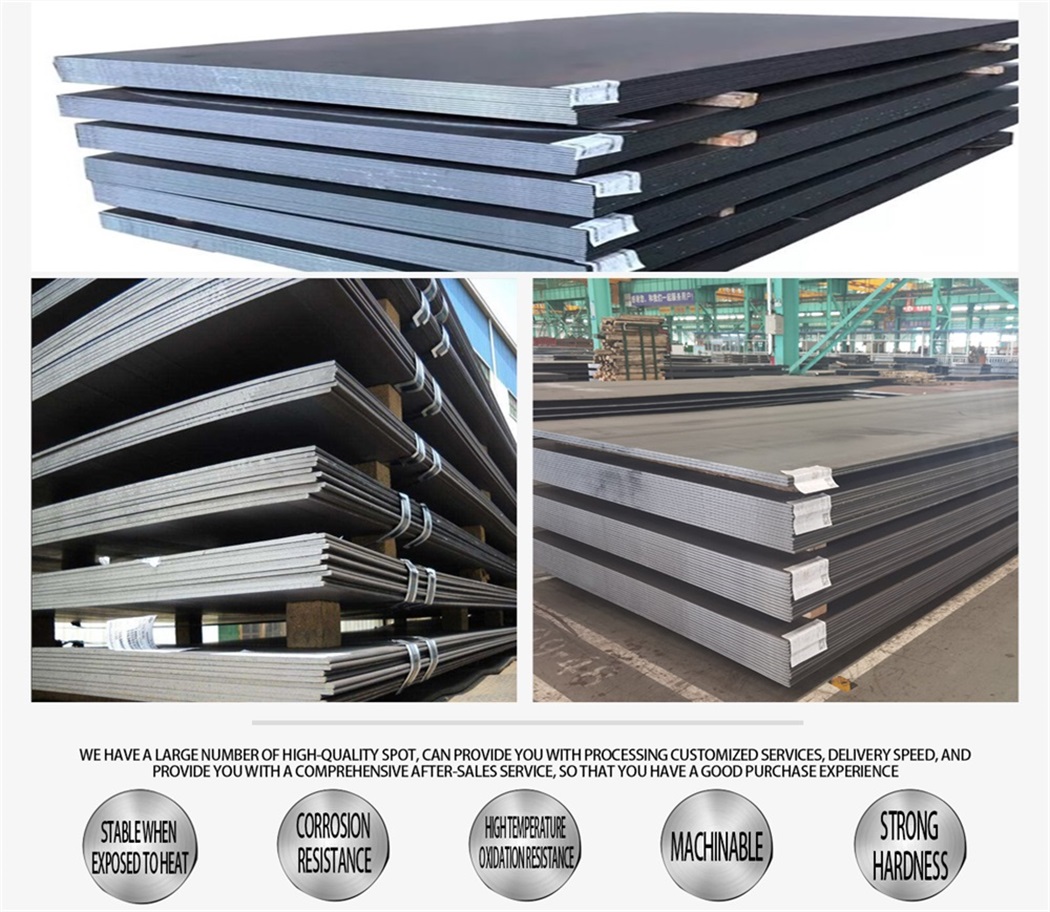

PRODUCT DISPLAY

PRODUCT PARAMETER

| Product Name | Cold Rolled Steel Plate |

|---|---|

| Material | Q345B,Q345C,Q345D,Q345E,Q390,Q390B,Q390C,Q390D,Q390E Q420,Q420B,Q420C,Q420D,Q420E,Q460,Q460D Q500C,Q500D,Q500E,Q550C,Q550D,Q550E Q620C,Q620D,Q620E,Q690A,Q690B,Q690C,Q690D,Q690E Q890C,Q890D |

| Thickness | 0.1-300mm.or as your request |

| Width | 600mm-1800mm or according to customer's special request |

| Length | 1m-12m or according to customer's special request |

| Standard | AISI,ASTM,JIS,DIN,GB,SUS |

| Tolerance | Thickness: +/-0.02mm, Width:+/-2mm |

| Technique | Hot Rolled,Cold Rolled |

| Application | Machine parts, Metal components, Agricultural machinery, Machine tools, Ships, Bridge etc |

| Payment Term | TT LC DP BL |

| Price Term | EXW/FOB/CIF/CFR |

| Sample | Available |

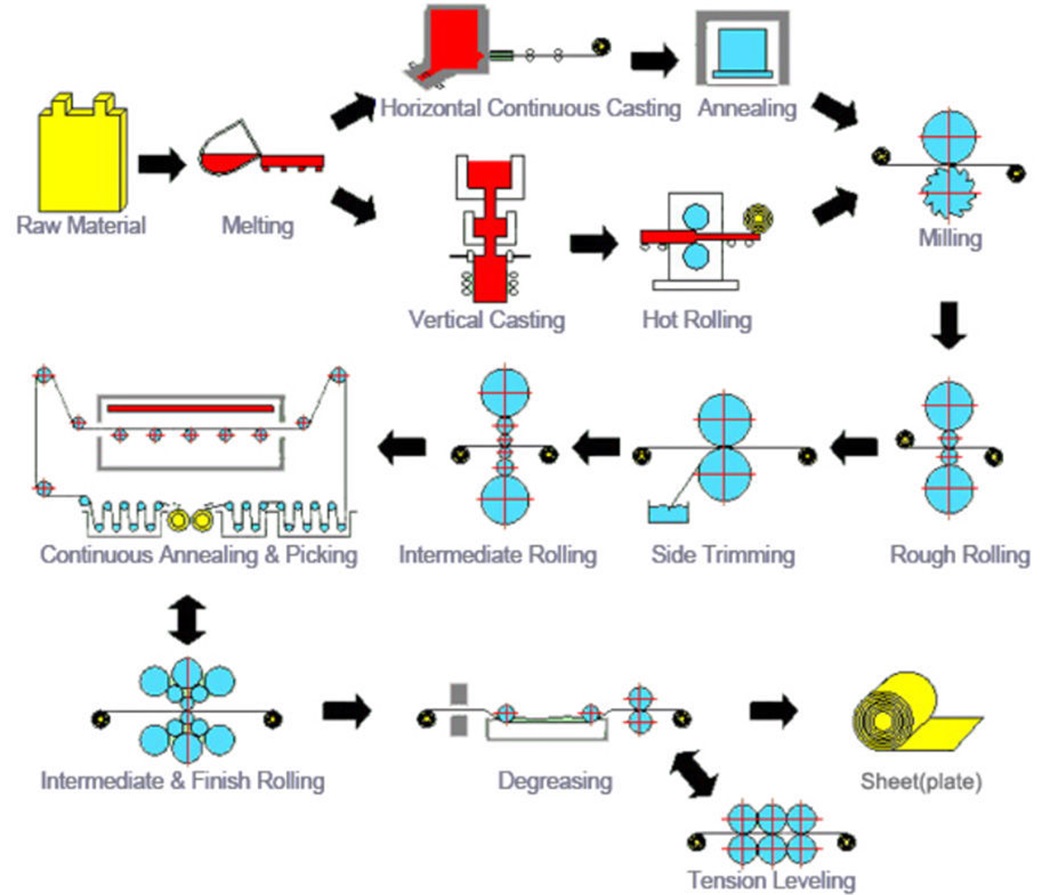

Production Process

OUR ADVANTAGES

COMPANY PROFILE

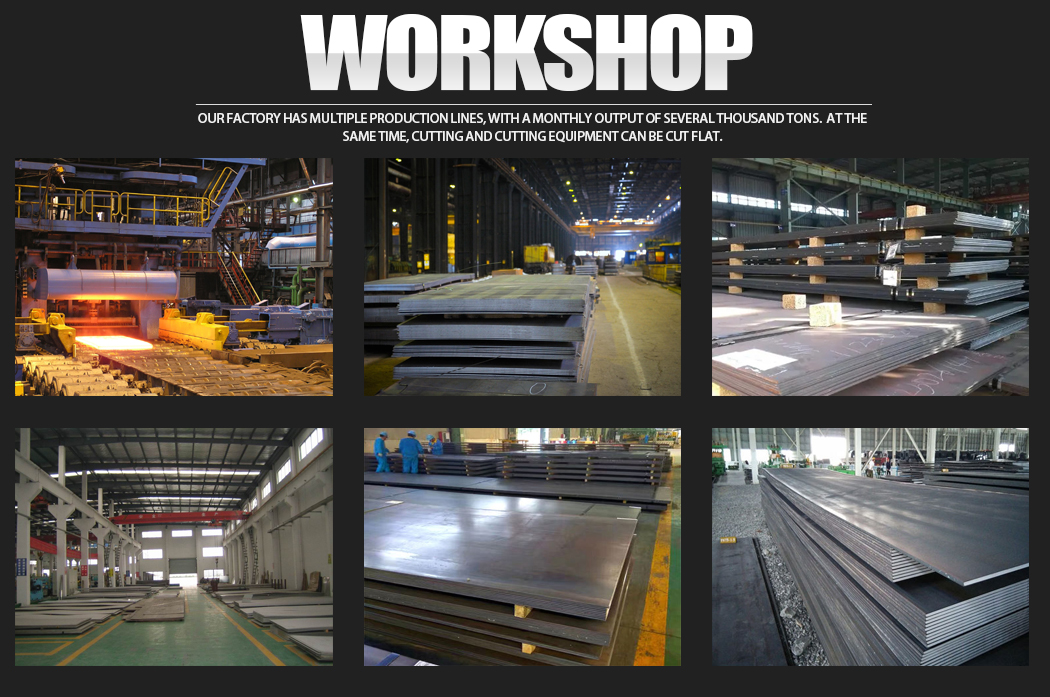

WORKSHOP

Spot wholesale guarantee product quality intimate service

The company's technical force, the processing equipment of processing technology, diverse processing methods, can provide users with aluminum plate shear cleaning ruler processing, aluminum bands longitudinal partial processing, thickness in aluminum alloy Panel sawtage ruler processing, aluminum plate surface covering processing, etc., to meet the needs of users with small batches, multi -varieties, multi -specifications, and multi -purpose needs

Real materials and real materials are uniform performance stable performance.

Have a lot of stocks, product quality assurance.

Refinery for many years of industry experience is worthy of your trust

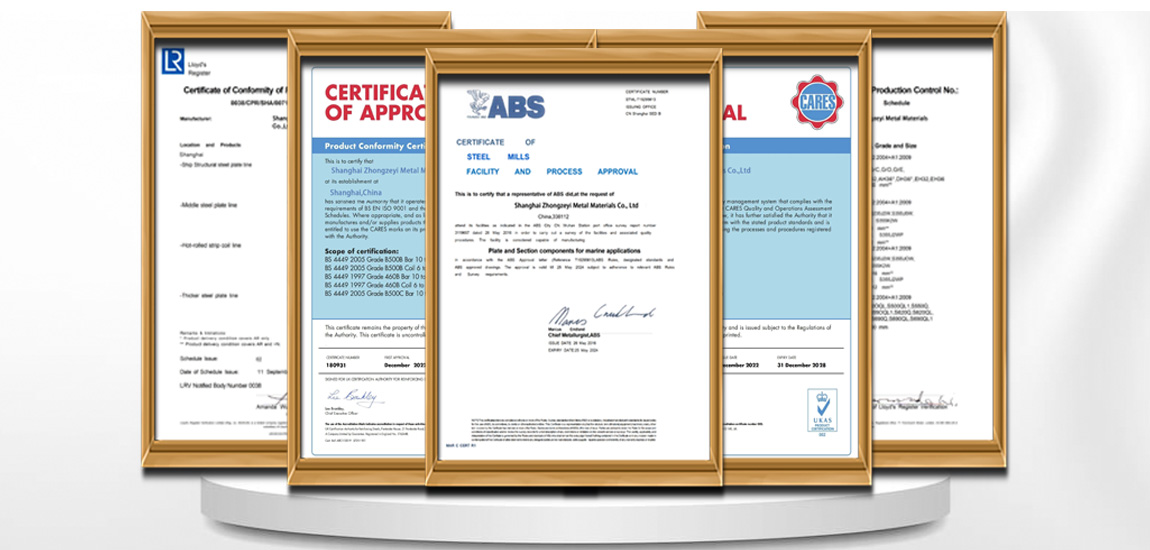

CERTIFICATIONS

CUSTOMER PRAISE

Based on high quality and warmly service, we have won clients all over the world, our products are widely trans to USA, Euro, India, Iran, Dubai, Russia, Thailand, South America, Singapore, and so on.Wrap with special anti rust paper; Covered with plastic film, packed with steel belt or wooden pallet or packed according to customer requirements.We have long-term cooperation with many experienced shipping companies and will find the most suitable mode of transportation for you.

PACKING& DELIVERY

Standard Export Package, Ensure the High Quality Delivery.

| Packaging Details: | Standard seaworthy packing(plastic&wooden) or according to the customer's requests |

| Delivery Detail: | 3-10days, mainly decided by the quantity of the order |

| Port: | Tianjing/Shanghai |

| shipping | Sea ship by container |

FAQ

Q1:Can I get samples before order ?

A:Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

Q2:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q3:What product information do I need to provide?

A:You need to provide the grade, length, width, diameter, thickness, coating and the number of tons you need to purchase.

Q4:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed.we accept third party inspection.

Q5:How do we trust your company?

A:We specialise in steel business for years , headquarter locates in Jinan, Shandong province, you are welcome to investigate in any ways, by all means, we have CE and ISO certificate, quality can be guaranteed, the most important point is that we ship enough weight as per the order.

CONTACT US

1.Send inquiry directly.

2.Send email.

3.Contacting via phone.

4.Contact sales staff.

shibushiwojnushuohuawomenjiuyongyuandoushiyzngyangde,nigaosuwodadiwomenzhiqinayouanaxieweneti,womenzhijandeewtnidaodikebukeyijiejue.zaishiwoemgnagwomenzhijiqnadaodidzennmene.

werrtg

spring

west

asjgowdhaogrhg